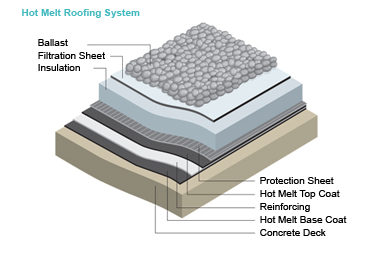

The modern, cost effective waterproofing for protected roofs, green roofs, podiums and water features

Hot Melt has been used on numerous new build developments in recent years as a waterproofing membrane of the structure, taking advantage of its speed and ease of application.

The Material

Hot Melt systems are rubberised bituminous products formulated from bitumen, synthetic or natural rubbers, oils and a filler such as clay. They are normally delivered to site in containers of varying size with separated cakes of material packed into them. These cakes are fed into a melter at a controlled temperature in the region of 200°C. The systems, which are liquid applied and therefore bond to the substrate, can be described as monolithic ensuring no possibility of water ingress.

Application

The nature of the material makes it possible to apply upstand and detail areas independently, prior to laying main deck areas. Detail application is by hand held floats or trowels, while the main deck is by speedy squeegy use. BriggsAmasco operatives, skilled in the traditional application of Mastic Asphalt, quickly became expert in the use of Hot Melt, which is applied in two layers to a nominal thickness of 6mm.

Benefits

- Essentially Hot Melt is a ‘protected system’ and is therefore ideal for use as part of an Inverted or Green Roof design. Most manufacturers offer complete packages for these options.

- A 100% bond can be achieved to a number of substrates including pre cast concrete, concrete blocks and suitably treated timber. (Generally lightweight structures are not suitable).

- Hot Melt is a fully bonded monolithic system which, when correctly applied, eliminates the possibility of water tracking below or behind the membrane.

- The systems offer flexibility across the temperature range, and in dry conditions, can be applied at low temperatures.

- As a fully protected system, it offers effective waterproofing for the design life of the building.

All BriggsAmasco branches are experienced in the application of Hot Melt monolithic membranes, particularly when used in conjunction with the installation of Green Roofs; a skill which has been achieved by all our contract personnel through regular training and numerous completed contracts.